Harnessing the cooling fans from F-150 pickups and the battery packs for its power tools, Ford on Tuesday announced that it will start making sorely-needed ventilators, respirators and medical face masks to help alleviate dire shortages as coronavirus cases surge across the country.

The company will work with GE Healthcare to start producing what Ford called a “simplified version” of GE’s existing ventilator design. The breathing devices are in short supply, with coronavirus compromising the respiratory system of patients, particularly those with more severe cases of the disease, also known as COVID-19.

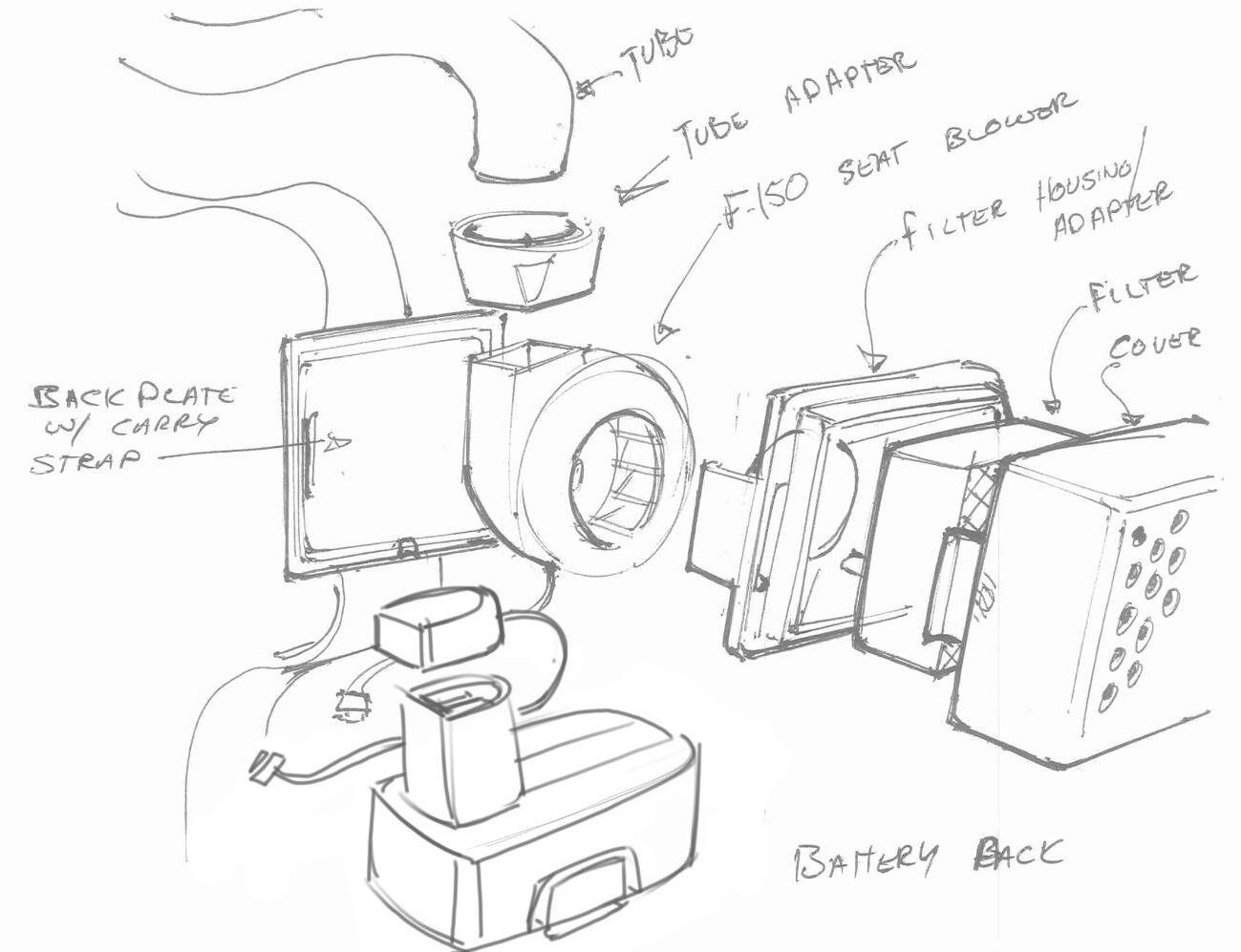

Ford will meanwhile partner with 3M to start building “Powered Air-Purifying Respirators.” The automaker will use “off-the-shelf parts,” it said in a statement, such as fans from the F-150’s cooled seats, portable-tool battery packs, and 3M-made HEPA filters to help screen contaminants like droplets that can carry coronavirus particles.

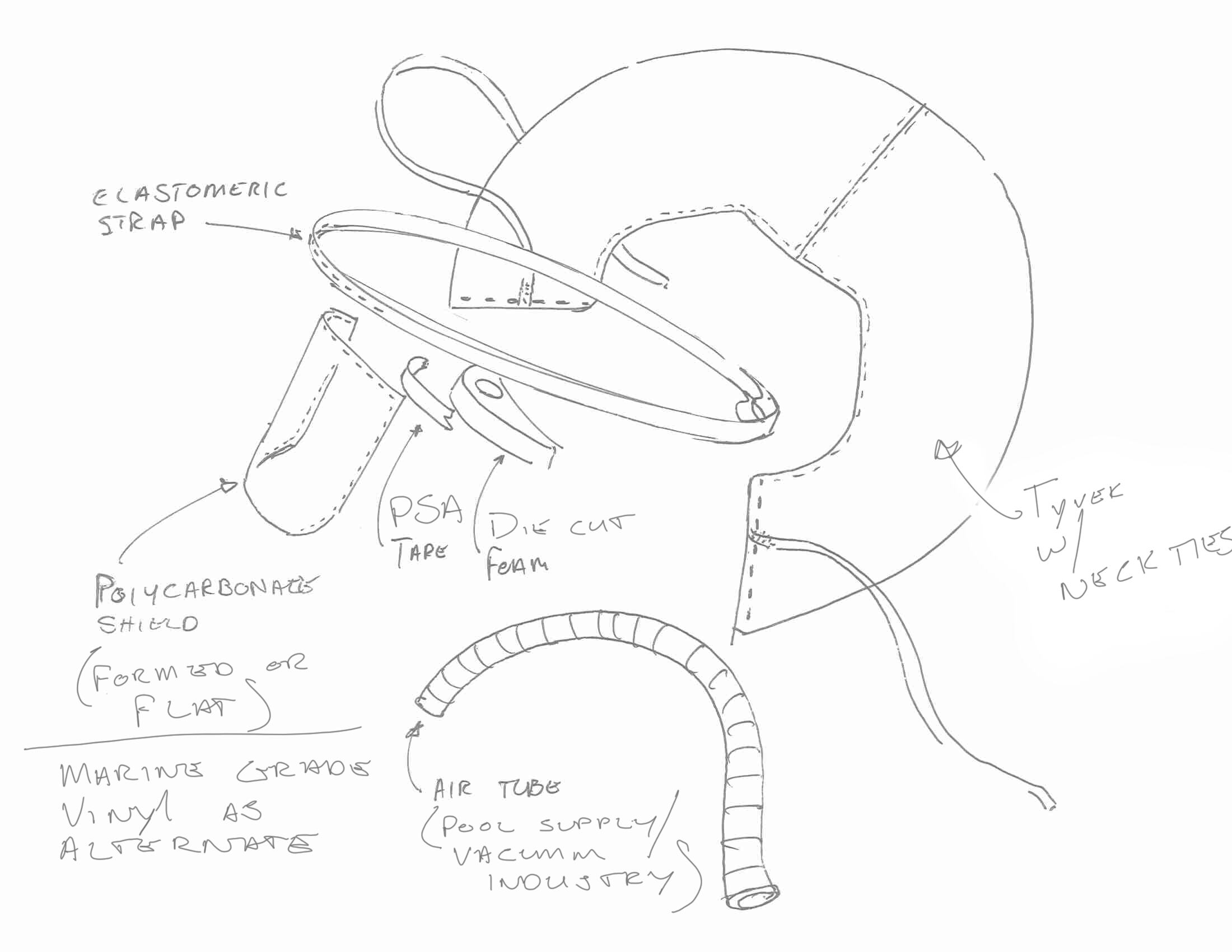

Ford also says it will begin using its in-house 3D manufacturing capability to start making as many as 100,000 transparent face shields a week. The masks will be made by a subsidiary, Troy Design and Manufacturing in Plymouth, Michigan.

As many as 75,000 face shields will be ready as soon as this week, the company said. There is not yet a delivery date for the ventilators.

“We don’t have specific timelines and numbers related to the design and release of the new ventilators, although of course this is of utmost importance to us and to Ford,” Tom Westrick, vice president and chief quality officer at GE Healthcare, said in a conference call with reporters Tuesday morning.

The companies are working with the U.S. Centers for Disease Control and using GE’s “global distribution” network to figure out where to send the ventilators once they are produced.

The announcement came one day after California Gov. Gavin Newsom confirmed that Tesla and SpaceX CEO Elon Musk had bought and shipped more than 1,000 ventilators for hospitals in the state. General Motors, which was the first U.S. automaker to confirm that it was considering making ventilators, on Friday said that it had partnered with Ventec Life Systems to help speed the construction of the breathing devices.

Ford is still exploring which manufacturing sites it might use for the ventilators. However, much of the company’s efforts will focus on expanding GE Healthcare’s existing manufacturing and logistics capacity.

“We’ve got a range of options in terms of facilities that we could leverage to actually increase through-put capability and scale,” Jim Baumbick, vice president for enterprise product line management at Ford, said during the media call. “What we’re focused on immediately is leveraging what GE Healthcare and 3M have already and expanding…Find those close parallels, open up potential new supply channels, and in some cases open up some additional arms and legs in some very skilled labor.”